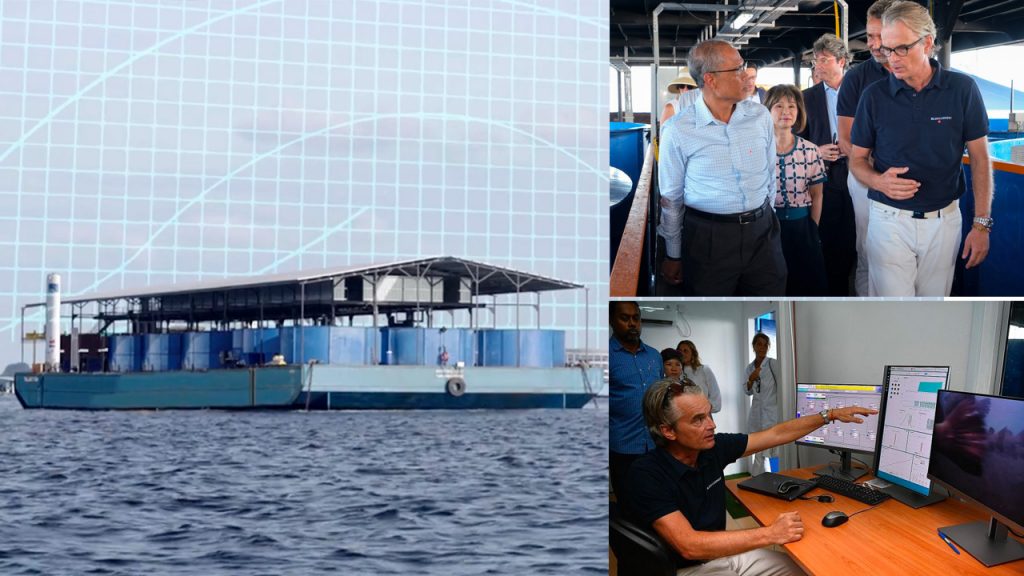

A short boat ride leads to a floating structure off our north-eastern coast that is quite unlike any kelong we’ve ever set eyes on. Singapore Aquaculture Technologies’ (SAT) smart fish farm – the first of its kind here – has multiple cylindrical tanks and is covered in solar panels. With Siemens as its technology partner, SAT is transforming the 3000 sqm offshore farm into what it calls Aquaculture 4.0, embracing automation and computerisation to make farming more efficient.

Getting better all the time

“Artificial intelligence” and “machine learning” might be the hottest buzzwords in every industry right now, but there’s no denying the usefulness of their applications. The system SAT implements has each tank constantly being monitored via video feed. The data drives its system to predict the biomass in each tank – basically measuring how big the fishes are getting without having to physically weigh them. The AI also recognises anomalous swim patterns, enabling the early detection of diseases and even when the fishes are hungry. The more data there is, the more accurate the system becomes.

Sustainable practices

Currently, 40 per cent of the farm’s energy needs is supplied by solar power. SAT is also working with universities to integrate nutrient- rich microalgae – produced by its parent company Wintershine – into fish feed. In turn, fish waste is used as nutrients for growing the algae – forming a partial closed loop.

Knowing where your food comes from

With increasing concerns about food safety and provenance, traceability has become more important than ever. Blockchain technology – not just for cryptocurrency – allows for quick and reliable tracing down the supply chain. A code scanned from a packet of frozen fish fillets can pull up information on everything from the processing date of the fish and the tank it was reared in to any medication (if any) administered.

Optimal operations

With all the systems in place, the farm will require half the amount of manpower previously needed. Every self-cleaning tank is monitored for environmental factors like water quality, oxygen level, biomass and swim patterns. These help the system to determine when to add feed and oxygen to the tanks. For example, the system automatically increases the oxygen input after feeding and as the tank’s biomass increases. Knowing exactly when and how much food to give the fish also significantly improves efficiency as feed can account for about 65 per cent of operating costs. Outside of a mechanical failure, almost everything can be observed and tweaked remotely – whether from a computer on- site or an iPad anywhere else.

On the farm

Safe from the outside world Pumped in from the sea, water is filtered, treated and channelled into the tanks where fishes are held in a controlled environment that protects them from harmful external factors like algae bloom or oil spills.

Tropical water fish Red snapper and barramundi hatchlings, also known as fingerlings, arrive from a hatchery to be raised to full size.

Full Steam Ahead When it is operating at full capacity in 2021, the farm will produce 350 tonnes of produce a year.

Feeding a growing population The world’s population is predicted to be almost 10 billion in 2050. With the planet already straining to feed the current 7 billion, protein sources have to shift. Among all the non-vegetable sources commonly consumed – barring insects – fishes have some of the lowest impact in terms of emissions and feed conversion. With limited space and resources, increasing farming efficiency becomes paramount. In Singapore, the government has set a “30 by 30” goal, where we’re working towards producing 30 per cent of our food needs by 2030.

Source The Peak

Photo by Sebastian Pena Lambarri on Unsplash